Vacuum Cycle Nucleation (VCN)

How to Clean Porous Metal Parts

Vacuum Cycle Nucleation (VCN) is the most exciting advancement in industrial cleaning since the introduction of ultrasonics. VCN provides superior performance in both aqueous and solvent applications.

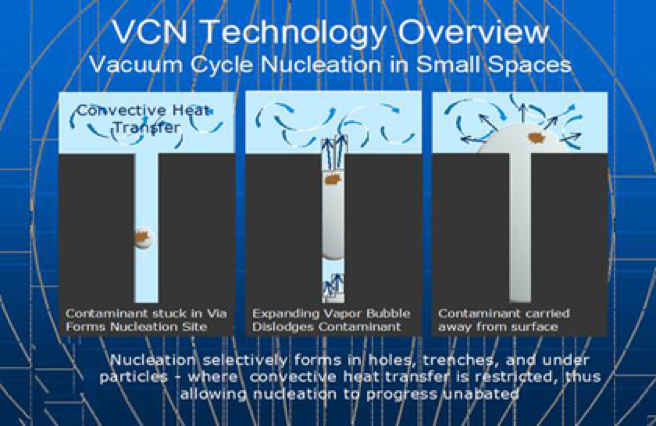

Nucleation selectively forms in the holes, trenches, and under particles where convective heat transfer is restricted, thus allowing nucleation to progress unabated.

Nucleation selectively forms in the holes, trenches, and under particles where convective heat transfer is restricted, thus allowing nucleation to progress unabated.

Solvent Cleaning of Wound Screen in Field Unit

The video shows wound screen 10” diameter roll producing a matrix of very small passages for fluid transfer. The screen comes from a stamping machine dripping with oil since it is wound immediately after stamping. The fluid is n-Propyl Bromide and the screen is made of copper.

The VCN process nucleates vapor bubbles on the screen forcing spent fluid from the screen matrix. When vacuum is paused, fresh fluid rushes into the screen to continue cleaning.

Vacuum Cycling Nucleation (VCN) for internal cleaning of parts:

- VCN works inside tight offsets. On the initial vacuum air is removed from the internals of the part.

- On the initial pressure cycle fluid is forced into the void spaces within the part.

- On the subsequent vacuum cycles vapor bubbles grow inside the part and force fluid from the internals of the part.

- Reactant chemicals, soluble material, particles and surfactant micelles are purged from the part during this cycle.

- On the subsequent pressure cycles fluid reenters the part’s internals bringing fresh treatment chemicals.

- Cycling continues until the part is fully processed.