Post Processing For Polymer Additive Manufacturing

Post processing of solid‐state powder sintering can lead to difficult, time consuming support material removal. The post processing often can even limit the design since support material in small areas presently can’t be removed with present day equipment. The same difficulties can be encountered with liquid phase beds although to a lesser extent. A new vacuum process has overcome the material removal problem. Examples of results are shown below.

Powder Bed Fusion Material Removal

Liquid Phase Bed Fusion Material Removal

Originally Printed Gear

Gear After One Hour

Gear After Three Hours

The gear shown above was treated in a 3% sodium hydroxide solution pulsing a vacuum to produce vapor within the part every 15 seconds. The VCN vacuum removes the spent solution from the internals of the gear and brings in fresh solution to continue dissolution. After 3 hours the gear was completely cleaned, and all the gears rotated freely. Generally, this part takes 48 hours in a circulation bath of 10% sodium hydroxide to remove all the material.

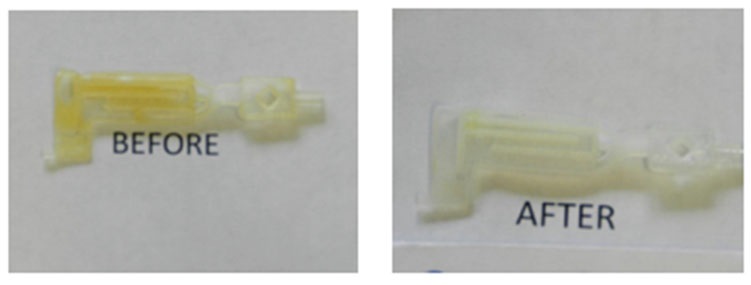

The internal removal of FDM support material from the parts shown on the left takes 1 to 2 days in an agitated bath. The part is shown on the right after 20 minutes in the VCN process. An additional 20 minutes removed all the internal material. Check out the below video to see this process in action.