VCN AND ULTRASONICS CLEANING

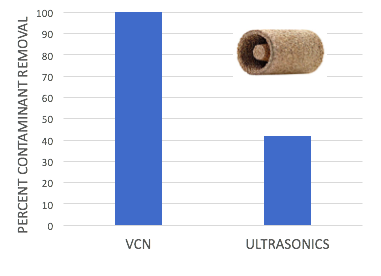

VCN AND ULTRASONICS CLEANING OF POROUS PARTS:

A porous filter having an average pore size of 10 microns was placed in a vacuum chamber and vacuum was pulled to less than 1 mmHg. Water soluble oil was brought into the chamber to submerge the filter. The chamber was brought back to atmospheric pressure and the filter was weighed to an accuracy of 1 mg.

Two filters were cleaned in a surfactant solution for two minutes, one in the VCN process and the second one in a 40 kHz ultrasonic bath using 100 watts/gallon energy. The results are shown in the graph below.

VCN and Ultrasonic Cleaning Efficiency of a Porous Filter

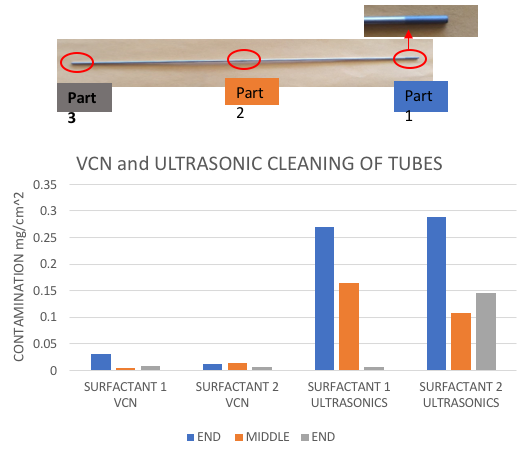

VCN AND ULTRASONICS CLEANING OF A TUBE:

11” long, 0.2” diameter tubes were filled with mineral oil and drained to coat the inside of the tubes with an average 0.25 mg/cm sq.

Two tubes were cleaned in a surfactant solution for two minutes, one in the VCN process and the second one in a 40 kHz ultrasonic bath using 100 watts/gallon energy. The remaining oil was measured using A total carbon analyzer. The results for three different locations in the tube as shown in the figure are shown in the graph below.