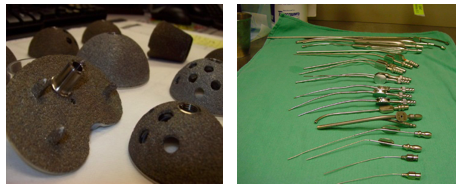

MEDICAL DEVICE CLEANING

Many medical devices contain high aspect ratio tubes. The cleaning of these devices requires gravity liquid fill and drain equipment, some form of liquid injection or manual scrubbing to assure cleaning. The problem is that tortuous paths, dead end paths or annular changes in diameter or seals can hinder these efforts to the point where contaminants can “hide” from the cleaning fluid. In addition, tight areas hinder the flow of fluid to either prevent fluid from reaching the contaminant or restrict fluid to such a low fluid rate that the liquid cleaning is not effective.

VCN grows vapor in these areas and forces fluid from the device. In simple terms it is better to push the fluid from the part rather than blow the fluid out by external means. Pushing the fluid, channels fluid through the least resistant path and leaves contaminant behind in small or dead-end areas. Dunking systems do not produce the internal agitation required to produce clean devices. Manual scrubbing can miss areas due to the complexity of the part or human error.

The VCN process has none of these restrictions. Since vapor likes to form in tight nucleation areas, vapor evacuates these areas of spent fluid and during a vacuum pause, fluid is allowed to refill the area. Cycling the process exposes the contaminated area to volumes of fresh cleaner in a short time to assure complete cleaning.

This video above shows how VCN nucleates vapor bubbles at tight areas to assure complete cleaning.